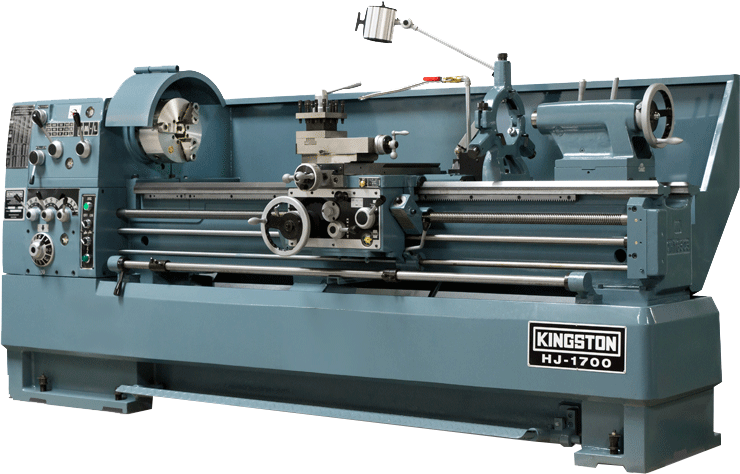

- HJ

- HR

- HD

- Enquire Now

Features

- 7.5 HP Motor for 230/460V, 3 Phase, 60 Cycle Wiring

- 2.25” Spindle Bore

- Spindle Nose: D1-6

- 12 Spindle Speeds (35 – 2000 RPM)

- 4-Way Tool Post, T-Slot Compound

- 4.7” Steady Rest with Roller Jaws

- 8” Drive Plate & 14” Face Plate

- Coolant System With Pump And Piping

- Hardened and Ground Bed and Cross Slide Ways

- 10” 3-Jaw Scroll Chuck

- LED Worklight

- Full-Length Splash Guard & Chuck Guard

Technical Specifications

| Capacity | HJ-1100 | HJ-1700 |

|---|---|---|

| Swing Over Bed | 17” | 17” |

| Swing Over Cross Slide | 10.6” | 10.6” |

| Swing in Gap | 24” | 24” |

| Distance Between Centers | 43.5” | 67” |

| Width of Bed | 11.75” | 11.75” |

| Length in Front of Face Plate | 5.9” | 5.9” |

| Height of Center from Leg Bottom | 42.3” | 42.3” |

| Headstock | HJ-1100 | HJ-1700 |

|---|---|---|

| Spindle Bore | 2.25″ | 2.25″ |

| Taper of Spindle Bore & Center | M.T. #6 x #4 | M.T. #6 x #4 |

| Type of Spindle Nose | D1-6 | D1-6 |

| Number of Spindle Speeds | 12 | 12 |

| Spindle Speeds | 35 – 2000 RPM | 35 – 2000 RPM |

| Gearbox | HJ-1100 | HJ-1700 |

|---|---|---|

| Number of Feed Changes | 16 | 16 |

| Range of Feeds per Revolution – Longitudinal | 0.0012” – 0.039” | 0.0012” – 0.039” |

| Range of Feeds per Revolution – Cross | 0.0004” – 0.0117” | 0.0004” – 0.0117” |

| Diameter and Pitch of Leadscrew | ø1.38”, 4 TPI | ø1.38”, 4 TPI |

| Range of Inch Threads | 2 – 72 TPI (44) | 2 – 72 TPI (44) |

| Range of Metric Pitches | 0.2 – 14mm (39 kinds) | 0.2 – 14mm (39 kinds) |

| Tool Slide | HJ-1100 | HJ-1700 |

|---|---|---|

| Maximum Travel of Compound | 5.7” | 5.7” |

| Maximum Travel of Cross Slide | 10.4” | 10.4” |

| Tailstock | HJ-1100 | HJ-1700 |

|---|---|---|

| Tailstock Quill Travel | 6.7” | 6.7” |

| Tailstock Quill Diameter | 2.3” | 2.3” |

| Taper in Tailstock Quill | M.T. #4 | M.T. #4 |

| Motor | HJ-1100 | HJ-1700 |

|---|---|---|

| Main Drive Motor | 7.5 HP | 7.5 HP |

| Coolant Pump Motor | 1/8 HP | 1/8 HP |

| Dimensions | HJ-1100 | HJ-1700 |

|---|---|---|

| Floor Space (L x W) | 98” x 41” | 120” x 41” |

| Weight | HJ-1100 | HJ-1700 |

|---|---|---|

| 3,520 lbs | 3,960 lbs |

Features

- 20 HP, 230V/460V, 3 Phase, 60 Cycle Motor, Switch & Wiring Complete

- 4.09” Spindle Bore

- Spindle Nose: D1-11 Camlock

- 16 Spindle Speeds: 8 – 800 RPM

- Headstock Spindle Adaptor: ASA-450 to MT#6

- 4-Way Rapid Traverse

- T-Slot on Tool Slide

- Hardened and Ground Bed and Cross Slide Ways

- 2-Speed Drive Tailstock Quill

- Coolant System with Pump and Piping

- Pull Drawer Chip (Coolant) Pan

Sliding Chuck Guard

Technical Specifications

| Capacity | 30″ | 34″ | 40″ |

|---|---|---|---|

| Swing Over Bed | 30″ | 34″ | 40″ |

| Swing Over Cross Slide | 20.7” | 25.1” | 31.0” |

| Swing Over Gap (Up to C.C. 160˚ Only) | 41.2” | 45.6” | 51.5” |

| Distance Between Centers | 80” / 120” / 160” / 200” / 240” / 280” / 320” | 80” / 120” / 160” / 200” / 240” / 280” / 320” | 80” / 120” / 160” / 200” / 240” / 280” / 320” |

| Width of Bed | 22″ | 22″ | 22″ |

| Height from Floor to Work Center | 46.5” | 48.6” | 51.5″ |

| Headstock | 30″ | 34″ | 40″ |

|---|---|---|---|

| Spindle Bore | 4.09” | 4.09” | 4.09” |

| Taper of Spindle Bore & Center | ASA #450 x MT #6 | ASA #450 x MT #6 | ASA #450 x MT #6 |

| Spindle Nose | D1-11, opt. A1-11 | D1-11, opt. A1-11 | D1-11, opt. A1-11 |

| Number of Spindle Speed | 16 | 16 | 16 |

| Spindle Speed | 8 – 800 RPM, 12 –1200 RPM (Opt) |

8 – 800 RPM, 12 –1200 RPM (Opt) |

8 – 800 RPM, 12 –1200 RPM (Opt) |

| Gear Box | 30″ | 34″ | 40″ |

|---|---|---|---|

| Number of Feed Changes | Fine (20), Normal (40), Coarse (30) | Fine (20), Normal (40), Coarse (30) | Fine (20), Normal (40), Coarse (30) |

| Range of Long. Feeds per Rev. |

0.00048” – 0.0168”, 0.0024” – 0.0337”, 0.0384” – 0.2694” |

0.00048” – 0.0168”, 0.0024” – 0.0337”, 0.0384” – 0.2694” |

0.00048” – 0.0168”, 0.0024” – 0.0337”, 0.0384” – 0.2694” |

| Longitudinal Cross | ½ of Longitudinal Feed | ½ of Longitudinal Feed | ½ of Longitudinal Feed |

| Leadscrew Dia. & Threads per Inch | 1.9” 2 TPI (P=12 mm) | 1.9” 2 TPI (P=12 mm) | 1.875” 2 TPI (P=12 mm) |

| Threading range – Whitworth | 2 to 28 TPI (40) / Coarse 5/8” to 8” Pitch (16) | 2 to 28 TPI (40) / Coarse 5/8” to 8” Pitch (16) | 2 to 28 TPI (40) / Coarse 5/8” to 8” Pitch (16) |

| Threading range – Metric | 1 to 14 Pitch (31) / Coarse 16 to 200 mm Pitch (61) | 1 to 14 Pitch (31) / Coarse 16 to 200 mm Pitch (61) | 1 to 14 Pitch (31) / Coarse 16 to 200 mm Pitch (61) |

| Threading range – Module | 0.5 to 7 M (20) / Coarse 8 to 56 M (30) | 0.5 to 7 M (20) / Coarse 8 to 56 M (30) | 0.5 to 7 M (20) / Coarse 8 to 56 M (30) |

| Threading range – D.P. | 56 to 4 D.P (40) / Coarse 3.5” to .5” D.P. (30) | 56 to 4 D.P (40) / Coarse 3.5” to .5” D.P. (30) | 56 to 4 D.P (40) / Coarse 3.5” to .5” D.P. (30) |

| Tool Slide | 30″ | 34″ | 40″ |

|---|---|---|---|

| Maximum Travel of Compound | 9.4” | 9.4” | 9.4” |

| Maximum Travel of Cross Slide | 21.2” | 21.2” | 21.2” |

| Tailstock | 30″ | 34″ | 40″ |

|---|---|---|---|

| Tailstock Quill Travel | 11.8” | 11.8” | 11.8” |

| Tailstock Quill Diameter | 5.1” | 5.1” | 5.1” |

| Tailstock Center | M.T. #6 | M.T. #6 | M.T. #6 |

| Motor | 30″ | 34″ | 40″ |

|---|---|---|---|

| Main Drive Motor | 20 HP (15kw) | 20 HP (15kw) | 20 HP (15kw) |

| Coolant Pump Motor | 1/4 HP | 1/4 HP | 1/4 HP |

| Dimensions | 30″ | 34″ | 40″ |

|---|---|---|---|

| Floor Space (L x W) | 193” / 233” / 256” / 312” / 358” / 390” / 431” x 82″ | 193” / 233” / 256” / 312” / 358” / 390” / 431” x 82″ | 193” / 233” / 256” / 312” / 358” / 390” / 431” x 82″ |

| Weight (lbs) | 10,230 / 11,770 / 14,300 / 15,840 / 18,370 / 20,420 / 23,500 | 10,450 / 11,990 / 14,520 / 16,060 / 18,590 / 20,640 / 23,650 | 10,940 / 12,250 / 14,790 / 16,330 / 18,860 / 20,900 / 23,950 |

Features

- 10 HP (22”) / 15 HP (26”), 230/460V 3 phase, 60 cycle, Switch & Wiring Complete

- 4.09” Spindle Bore

- Spindle Nose: D1-8 (22”) / D1-11 (26”) Camlock

- 12 Spindle Speeds (13 – 1200 RPM)

- Lead Screw: 4 TPI (22”) / 2 TPI (26”)

- 10” Steady Rest with Roller Jaws

- 4-Way Tool Post, T-Slot Compound

- Rapid Traverse Standard on 90 C.C. and Longer Lathes

- Coolant System With Pump And Piping

- Hardened and Ground Bed and Cross Slide Ways

- Pull Drawer Chip (Oil) Pan

- LED Worklight

- Full-Length Splash Guard & Chuck Guard

Technical Specifications

| Capacity | HD-22 | HD-26 |

|---|---|---|

| Swing Over Bed | 22″ | 26″ |

| Swing Over Cross Slide | 13″ | 17.5″ |

| Swing In Gap | 31.3″ | 35.1” |

| Gap Width in Front of the Face Plate | 10.6” | 10.6” |

| Distance Between Centers | 35″ / 60” / 90” / 120” / 160” | 35″ / 60” / 90” / 120” / 160” |

| Width of Bed | 15.7” | 15.7” |

| Height of Center from Leg Bottom | 42.0” | 44.3” |

| Headstock | HD-22 | HD-26 |

|---|---|---|

| Spindle Bore | 4.09″ | 4.09″ |

| Taper of Spindle Bore & Center | M.T. #7 x #5 | M.T. #7 x #5 |

| Type of Spindle Nose | D1-8 | D1-11 |

| Number of Spindle Speed | 12 | 12 |

| Spindle Speed | 13 – 1200 RPM | 13 – 1200 RPM |

| Gearbox | HD-22 | HD-26 |

|---|---|---|

| Number of Feed Changes | 16 | 16 |

| Range of Feeds per Revolution – Longitudinal | 0.0012” – 0.039” | 0.0012” – 0.039” |

| Range of Feeds per Revolution – Cross | 0.0004” – 0.0117” | 0.0007” – 0.0188” |

| Leadscrew Diameter & Threads / Inch | 1.77”, 4 TPI | 1.77”, 2 TPI |

| Range of Inch Threads | 2 – 72 (44) | 1 – 42 (48) |

| Range of Metric Pitches | 0.2 – 14 (39) | 0.2 – 14 (39) |

| Tool Slide | HD-22 | HD-26 |

|---|---|---|

| Maximum Travel of Compound | 9.5” | 9.5” |

| Maximum Travel of Cross Slide | 15.8” | 15.8” |

| Tailstock | HD-22 | HD-26 |

|---|---|---|

| Tailstock Quill Travel | 9.8” | 9.8” |

| Tailstock Quill Diameter | 2.9” | 2.9” |

| Taper in Tailstock Quill | M.T. #5 | M.T. #5 |

| Motor | HD-22 | HD-26 |

|---|---|---|

| Main Drive Motor | 10 HP | 15 HP |

| Coolant Pump Motor | 1/8 HP | 1/8 HP |

| Dimensions | HD-22 | HD-26 |

|---|---|---|

| Floor Space (L x W x H) | 87″ / 114” / 146” / 177” / 217” x 47″ x 59” | 87″ / 114” / 146” / 177” / 217” x 47″ x 59” |

| Weight | HD-22 | HD-26 |

|---|---|---|

| 35″ | 5,100 lbs | 5,300 lbs |

| 60″ | 5,300 lbs | 5,500 lbs |

| 90″ | 6,200 lbs | 6,300 lbs |

| 120″ | 6,700 lbs | 7,000 lbs |

| 160″ | 7,000 lbs | 8,000 lbs |