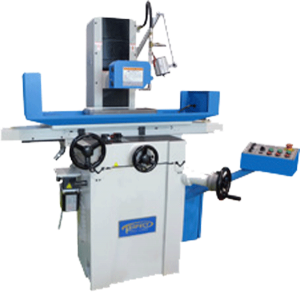

- PFG-1545H

- PFG-2045H

- PFG-2550H

- PFG-1545AH

- PFG-2045AH

- PFG-2550AH

- PFG-3060AH

- PFG-D4080AH

- Enquire Now

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

| SPECIFICATE | UNIT | PFG-1545H |

|---|---|---|

| Grinding surface of table | mm | 150×450 (6″x18″) |

| Max. distance center of spindle to table | mm | 450 (18″) |

| Total Max. safety table load | kgs | 144 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 900 |

| Packing gross weight | Kgs | 1100 |

| Floor space (AxBxC) | mm | 2080x1200x1700 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

| SPECIFICATE | UNIT | PFG-2045H |

|---|---|---|

| Grinding surface of table | mm | 200×450 (8″x18″) |

| Max. distance center of spindle to table | mm | 450 (18″) |

| Total Max. safety table load | kgs | 150 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 950 |

| Packing gross weight | Kgs | 1150 |

| Floor space (AxBxC) | mm | 2080x1200x1700 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

| SPECIFICATE | UNIT | PFG-2550H |

|---|---|---|

| Grinding surface of table | mm | 250×500 (10″x20″) |

| Max. distance center of spindle to table | mm | “500 (20″”) [Option:600 (24″”)]” |

| Total Max. safety table load | kgs | 250 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 1350 |

| Packing gross weight | Kgs | 1550 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

NC Auto Down Feed System (AD5 type)(Option)

Except for the H series, the AH, and AHR models are available to equip with an optional NC auto down feed system (AD5) to become 3 axes fully automated for greatly increasing operational convenience.

| SPECIFICATE | UNIT | PFG-1545AH |

|---|---|---|

| Grinding surface of table | mm | 150×450 (6″x18″) |

| Max. distance center of spindle to table | mm | 450 (18″) |

| Total Max. safety table load | kgs | 144 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 900 |

| Packing gross weight | Kgs | 1100 |

| Floor space (AxBxC) | mm | 2080x1200x1700 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

NC Auto Down Feed System (AD5 type)(Option)

Except for the H series, the AH, and AHR models are available to equip with an optional NC auto down feed system (AD5) to become 3 axes fully automated for greatly increasing operational convenience.

| SPECIFICATE | UNIT | PFG-2045AH |

|---|---|---|

| Grinding surface of table | mm | 200×450 (8″x18″) |

| Max. distance center of spindle to table | mm | 450 (18″) |

| Total Max. safety table load | kgs | 150 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 950 |

| Packing gross weight | Kgs | 1150 |

| Floor space (AxBxC) | mm | 2080x1200x1700 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

NC Auto Down Feed System (AD5 type)(Option)

Except for the H series, the AH, and AHR models are available to equip with an optional NC auto down feed system (AD5) to become 3 axes fully automated for greatly increasing operational convenience.

NC Auto Parallel Dressing & Compensating System (Option)

The optional NC auto parallel dressing & compensating system is available to equip with an optional NC auto down feed system (AD5 type), greatly increasing the grinding efficiency.

| SPECIFICATE | UNIT | PFG-2550AH |

|---|---|---|

| Grinding surface of table | mm | 250×500 (10″x20″) |

| Max. distance center of spindle to table | mm | “500 (20″”) [Option:600 (24″”)]” |

| Total Max. safety table load | kgs | 250 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 180x13x31.75 |

| Spindle motor | HP | 2 |

| Machine net weight | Kgs | 1350 |

| Packing gross weight | Kgs | 1550 |

| Floor space (AxBxC) | mm | 2340x1500x1800 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

NC Auto Down Feed System (AD5 type)(Option)

Except for the H series, the AH, and AHR models are available to equip with an optional NC auto down feed system (AD5) to become 3 axes fully automated for greatly increasing operational convenience.

NC Auto Parallel Dressing & Compensating System (Option)

The optional NC auto parallel dressing & compensating system is available to equip with an optional NC auto down feed system (AD5 type), greatly increasing the grinding efficiency.

| SPECIFICATE | UNIT | PFG-3060AH |

|---|---|---|

| Grinding surface of table | mm | 300×600 (12″x24″) |

| Max. distance center of spindle to table | mm | 500 (20″) [Option:600 (24″)] |

| Total Max. safety table load | kgs | 300 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 355x38x127 |

| Spindle motor | HP | 5 |

| Machine net weight | Kgs | 1700 |

| Packing gross weight | Kgs | 1950 |

| Floor space (AxBxC) | mm | 2630x1550x1800 |

Optimized Structure

The major parts are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Precision Spindle Design

The spindle runs in a class P4 high precision angular contact bearing, assuring run-out accuracy in 2 μm. The cartridge-type spindle is completely sealed and lubricated for long working lifetime, providing high accuracy grinding and a long service life.

Turcite-B on Slideways

The X and Z axes slideways are coated with Turcite-B for stable movement and long term accuracy.

NC Auto Down Feed System (AD5 type)(Option)

Except for the H series, the AH, and AHR models are available to equip with an optional NC auto down feed system (AD5) to become 3 axes fully automated for greatly increasing operational convenience.

NC Auto Parallel Dressing & Compensating System (Option)

The optional NC auto parallel dressing & compensating system is available to equip with an optional NC auto down feed system (AD5 type), greatly increasing the grinding efficiency.

| SPECIFICATE | UNIT | PFG-D4080AH |

|---|---|---|

| Grinding surface of table | mm | 400X800 (16″x32″) |

| Max. distance center of spindle to table | mm | 550 (22″) [Option:650 (25″)] |

| Total Max. safety table load | kgs | 300 |

| Table guideway | V & FLAT WAY | |

| Wheel dimension | mm | 405x50x127 |

| Spindle motor | HP | 5 |

| Machine net weight | Kgs | 3250 |

| Packing gross weight | Kgs | 3500 |

| Floor space (AxBxC) | mm | 3450x2050x1900 |